Integrating Artificial Intelligence (AI) and advanced technology by polyvinyl alcohol (PVA) suppliers marks a transformative era in the chemical industry, significantly enhancing efficiency, innovation, and sustainability. PVA, a versatile synthetic polymer, is utilized in various applications, including textile sizing, paper coating, adhesives, and biodegradable films. As the demand for PVA expands across diverse sectors, suppliers increasingly adopt AI and technology to meet the growing market needs while addressing environmental concerns.

Innovations in Manufacturing Processes

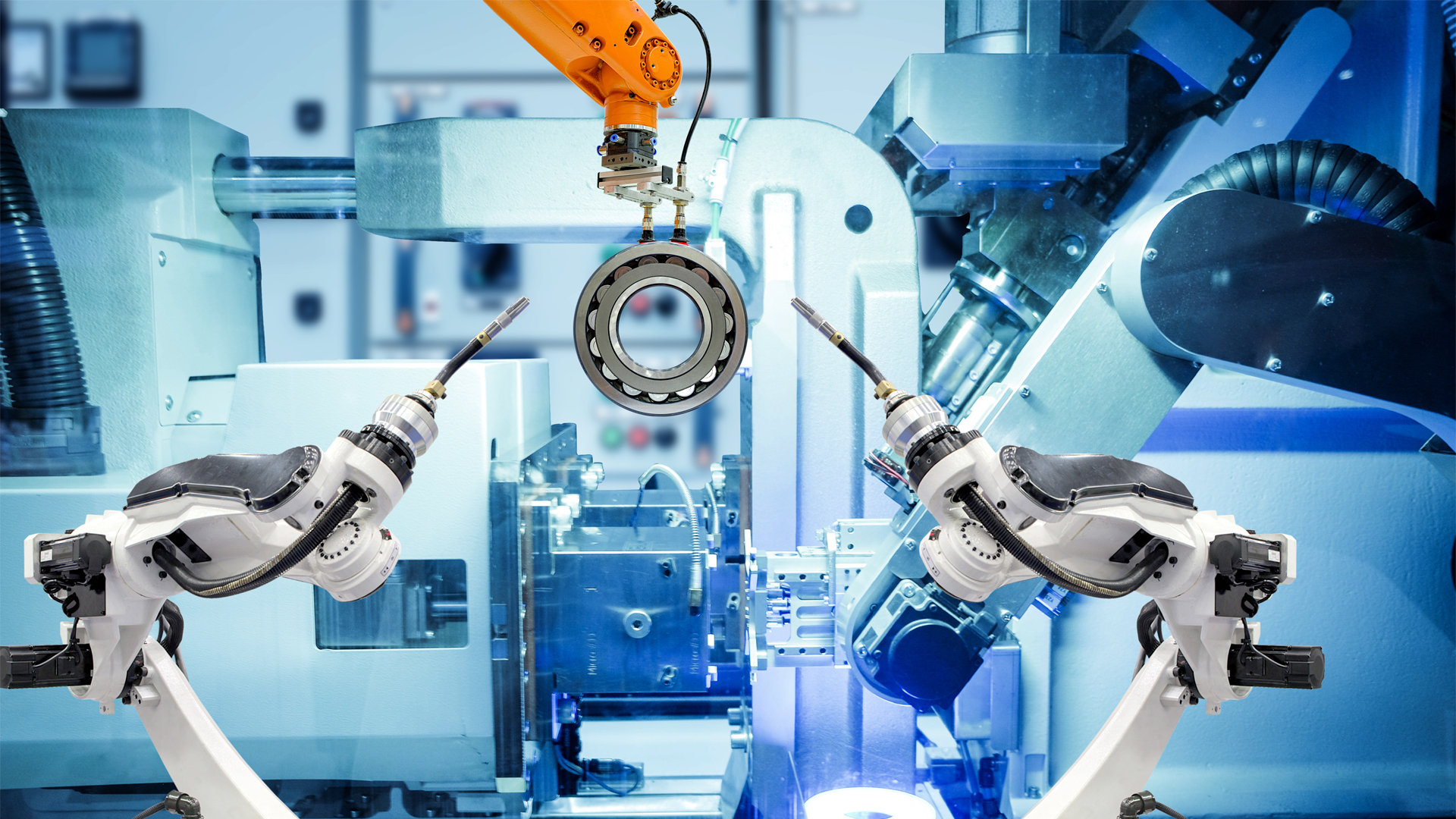

One primary area where AI has made a substantial impact is in the optimization of PVA production processes. By implementing AI-driven predictive maintenance, suppliers can predict equipment failures before they occur, reducing downtime and maintaining continuous production flow. AI algorithms analyze data from sensors embedded in machinery to identify patterns or anomalies that may indicate imminent failure, allowing for preemptive maintenance and repairs.

Additionally, AI and machine learning (ML) models optimize the chemical reactions of PVA synthesis. Model prediction of diverse reaction parameters accurateness, allows to achieve the entire polymer characteristics efficiently, e.g. molecular weight, and degree of hydrolysis, which in turn reduces the waste and the quality of product is improved.

Enhanced Quality Control

AI technologies have revolutionized quality control processes in PVA production. Computer vision systems, combined with deep learning algorithms, are used for real-time manufacturing process monitoring to detect defects or inconsistencies in the product. This ensures a consistently high-quality product and significantly reduces waste, as issues can be identified and rectified promptly.

Sustainable Practices and Waste Reduction

Sustainability is a pressing concern in the chemical manufacturing sector, and PVA suppliers are leveraging technology to address these environmental challenges. AI-powered systems aid in optimizing resource usage, including water and energy, thus minimizing the ecological footprint of production processes. For instance, AI can forecast energy consumption patterns, enabling suppliers to adjust their operations accordingly to reduce energy usage during peak times.

Moreover, technology is crucial in advancing recycling and waste management practices.One of the key breakthroughs in this area has been the emergence of AI-driven models that enable better development of enzymatic degradation and chemical recycling of PVA. Such models are gradually helping to find more sustainable routes for disposal of PVA goods. The reason behind that is to plow these technologies and they will break used PVA into the monomers and then these monomers can be made available for manufacturing new polymers and that leads to the circular economy.

Supply Chain and Logistics Optimization

AI and technology also offer solutions to enhance the efficiency of supply chains and logistics for PVA suppliers. AI-driven analytics and forecasting tools enable suppliers to predict demand more accurately, ensuring optimal stock levels and reducing the risk of shortages or overstocking. Furthermore, logistics operations benefit from AI through route optimization for transportation, minimizing delivery times, and reducing carbon emissions.

Future Prospects

As AI and technology evolve, the potential for innovation in the PVA industry is boundless. Ranging from smart polymers that have the ability to adapt, to the implementation of blockchain for grabbing the true potential of secure and transparent supply chains, the future is full of fantastic possibilities for PVA suppliers and their customers.

In conclusion, adopting AI and advanced technology by polyvinyl alcohol suppliers signifies a leap forward in the industry, driving efficiency, quality, and sustainability. Already at this stage of their maturity, such technologies carry great potential, creating new advantages and tasks which will direct the future of PVA manufacturing and industry altogether.

Revolutionizing PVA Production with AI

Apart from AI and other Technologies coming together to make PVA, new methods bring about efficiency and changes in the different stages of production and supply. Below are examples of how AI is revolutionizing PVA production, enhancing efficiency, product quality, and sustainability:

Process Optimization

- Predictive Maintenance: AI algorithms analyze operational data from production machinery to predict potential failures before they occur. This proactive approach reduces downtime and maintains a steady production rate, ensuring that the supply of PVA meets market demand consistently.

- Reaction Parameter Optimization: Machine learning models optimize the chemical reactions involved in PVA synthesis. By accurately predicting the effects of different reaction parameters, manufacturers can efficiently achieve the desired polymer characteristics, such as molecular weight and degree of hydrolysis. This reduces raw material wastage and improves the quality of the final product.

Quality Control

- Computer Vision for Defect Detection: Advanced computer vision systems, powered by deep learning monitor the PVA production line in real-time to identify defects or inconsistencies in the product. Immediate detection and correction of these issues ensure that only high-quality PVA reaches the market.

Sustainability

- Resource Optimization: AI systems offer significant advancements in managing and optimizing the use of resources, including water and energy. Predictive analytics help forecast energy consumption patterns, allowing manufacturers to adjust operations to minimize environmental impact.

- Recycling and Waste Management: Innovations in AI facilitate the development of new methods for recycling PVA, including enzymatic degradation and chemical recycling. These technologies support the breakdown of PVA waste into its constituent components, which can be reused to produce new polymers, contributing to a circular economy.

Supply Chain and Logistics

- Demand Forecasting: AI-driven tools analyze market trends and historical data to forecast demand for PVA accurately. This ensures optimal inventory levels, reducing the risk of overproduction or shortages.

- Logistics Optimization: AI algorithms optimize logistics and transportation routes, reducing delivery times and lowering carbon emissions. Efficient logistics are crucial for maintaining the competitiveness of PVA suppliers in the global market.

Smart PVA Products

- Development of Smart Polymers: AI and technology are revolutionizing the production processes and aiding in the research and development of smart PVA polymers. These polymers can change their properties in response to environmental stimuli, opening up new applications in drug delivery systems, innovative packaging, and water treatment technologies.