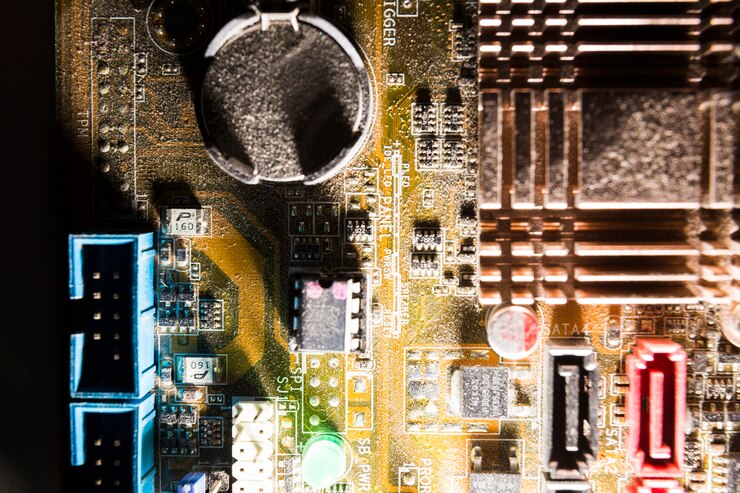

In the fast-paced world of electronics, the demand for more complex and compact devices continues to grow. At the heart of these advancements lies the Printed Circuit Board (PCB), a fundamental component that supports and connects electronic components. Among the various types of PCBs, the double sided PCB has emerged as a versatile and widely used option, offering numerous benefits for both simple and complex electronic designs.

Understanding Double Sided PCBs

A double sided PCB, also known as a double layer PCB, features conductive copper layers on both the top and bottom sides of the board. This structure allows for more complex circuitry and greater component density compared to single sided PCBs, which only have copper on one side. The double sided PCB is connected through holes (vias) that enable the electrical connections between the two layers.

Key Features and Benefits of Double Sided PCBs

- Increased Circuit Density: By utilizing both sides of the board, double sided PCBs can support a higher density of components and interconnections. This is particularly beneficial for designs that require more complex circuits in a smaller footprint.

- Enhanced Design Flexibility: The ability to place components and routes on both sides of the board provides greater flexibility in circuit design. This facilitates the creation of more intricate and compact layouts, which are essential for modern electronic devices.

- Improved Performance: Double sided PCBs can reduce the overall electrical load by distributing components across two layers. This helps in minimizing signal interference and crosstalk, leading to better performance and reliability of the electronic device.

- Cost-Effective: Although slightly more expensive than single sided PCBs, double sided PCBs offer a cost-effective solution for many applications. They strike a balance between complexity and cost, making them suitable for a wide range of products from consumer electronics to industrial machinery.

Applications of Double Sided PCBs

Double sided PCBs are used across a myriad of industries due to their versatility and efficiency. Some common applications include:

- Consumer Electronics: Smartphones, tablets, and other portable devices often utilize double sided PCBs to maximize functionality within a compact space.

- Automotive Industry: Modern vehicles incorporate numerous electronic systems for control, safety, and entertainment, many of which rely on double sided PCBs.

- Industrial Equipment: Automation systems, machinery, and industrial controls benefit from the enhanced reliability and performance of double sided PCBs.

- Medical Devices: Advanced medical equipment, such as diagnostic instruments and monitoring systems, use double sided PCBs to meet stringent performance and reliability requirements.

Selecting a PCB Manufacturer

Choosing the right PCB manufacturer is crucial for ensuring the quality and performance of double sided PCBs. Here are some factors to consider:

- Expertise and Experience: Look for manufacturers with a proven track record in producing high-quality double sided PCBs. Their experience can greatly impact the reliability and precision of the final product.

- Technological Capabilities: Ensure the manufacturer has advanced equipment and technology to produce complex double sided PCBs with precise specifications. This includes state-of-the-art fabrication and testing facilities.

- Quality Assurance: A reputable PCB manufacturer will have stringent quality control processes in place to ensure each board meets industry standards. This includes thorough testing and inspection at various stages of production.

- Customization Options: Different applications may require specific PCB features or materials. Choose a manufacturer that offers customization options to meet your unique design requirements.

- Customer Support: Reliable customer support is essential for addressing any issues or questions that may arise during the design and manufacturing process. Opt for a manufacturer known for excellent customer service.

Conclusion

Double sided PCBs play a critical role in the advancement of modern electronics, offering a perfect balance of complexity, efficiency, and cost-effectiveness. As technology continues to evolve, the demand for these versatile boards will only increase. By partnering with a reputable PCB manufacturer, businesses can ensure they receive high-quality double sided PCBs that meet their specific needs, driving innovation and performance in their electronic products.