Gas lines serve as the lifeline of numerous households, furnishing a dependable energy source for various purposes such as heating, cooking, and more. However, as with any complex system, gas lines are susceptible to wear and tear over time, necessitating repairs. Familiarizing oneself with the fundamental steps involved in the repair process is paramount to maintaining the safety and efficiency of one’s home.

Evaluation and Examination

The gas line repair process begins with a comprehensive evaluation and examination by seasoned professionals. This thorough assessment requires a detailed examination of the entire line system to identify any present leaks, damages, or potential issues that could pose risks to safety or efficiency. Using specialized tools and equipment, professionals delve beyond superficial visual inspections to uncover hidden problems that might go unnoticed. This meticulous method guarantees a comprehensive examination of every facet of the system, facilitating precise and efficient repairs.

Gas Supply Shutdown

Upon identifying issues within the gas line system, the subsequent action promptly initiates the supply shutdown to the affected area. This proactive measure is indispensable in mitigating the risks of potential leaks or other hazards that could arise during the repair phase. Deciding whether to turn off the supply depends on the extent of damage or the specific repair requirements. This assessment is crucial for ensuring the necessary precautions to address the issues effectively while minimizing potential risks. In some cases, it may be imperative to turn off the supply not only for the affected area but also for adjoining zones to prevent any potential spread of hazards.

Repair or Replacement

With the gas supply safely halted, repair activities commence without delay. The nature of the problem dictates whether repair involves fixing the existing line or completely replacing damaged segments. In cases where these lines are outdated, upgrading or replacing them becomes imperative to ensure optimal safety and efficiency. Employing suitable repair techniques and materials, skilled professionals execute repairs or replacements swiftly and effectively.

Testing and Inspection

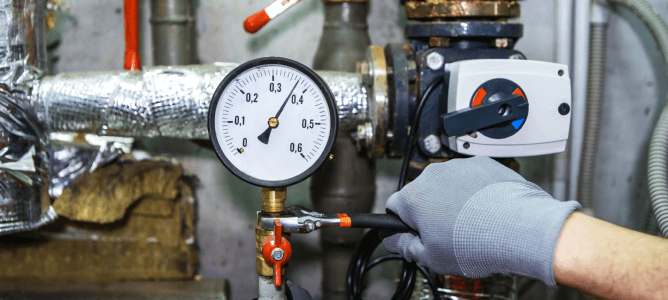

Following repair completion, rigorous testing and inspection of the gas line system are conducted to validate its functionality. This involves pressuring the system to detect residual leaks or performing additional tests to verify repair integrity. Thoroughness in this stage is crucial for preempting potential safety hazards or future issues with the system, emphasizing the significance of meticulous attention to detail.

Final Safety Verification

Before restoring the gas supply to the affected area, final safety verifications are carried out to ensure every component meets optimal working standards. These verifications encompass a detailed examination of connections, verification of pressure levels, and affirmation of adherence to all safety protocols. The supply is reinstated only after completing these checks, granting homeowners the confidence to resume regular use of their gas appliances.

The gas line repair process constitutes a pivotal aspect of home maintenance, safeguarding the safety and efficiency of gas-powered appliances. Equipping oneself with an understanding of the fundamental steps in the repair process empowers homeowners to address arising issues promptly. Each phase, from thorough evaluation to exhaustive testing, is crucial in maintaining the integrity of the gas line system. Entrusting trained professionals and adhering to stringent safety protocols ensures that the lines remain in capable hands, assuring homeowners of a safe and efficient home environment.