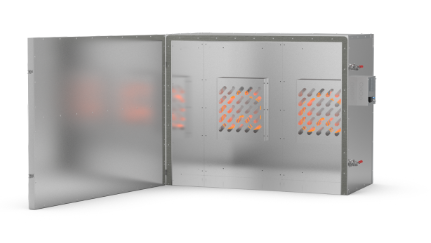

Industrial powder coating ovens are essential equipment for businesses involved in the powder coating process. These ovens are used to cure or bake the powder coating onto the surface of the material being coated. Choosing the right size industrial powder coating oven is crucial for the efficiency and effectiveness of your operations. In this guide, we will discuss the factors to consider when selecting the right size oven for your business.

1. Consider the Size of the Parts Being Coated

One of the primary factors to consider when choosing the right size industrial powder coating oven is the size of the parts being coated. You need to ensure that the oven is large enough to accommodate the parts without overcrowding. Overcrowding the oven can result in uneven curing and poor-quality finishes. Measure the dimensions of the largest parts you will be coating to determine the internal dimensions of the oven you need.

2. Production Capacity

Another important factor to consider is the production capacity of your business. The size of the oven should be able to handle the volume of parts you need to coat within a given timeframe. If you have high production demands, you may need a larger oven or multiple ovens to meet your requirements efficiently. Consider the throughput and cycle times of the oven to ensure it aligns with your production needs.

3. Space Constraints

It is essential to consider the space available in your facility when choosing the size of the industrial powder coating oven. Measure the area where the oven will be placed to ensure it fits comfortably without obstructing workflow or causing safety hazards. Additionally, consider the clearance requirements for the oven to ensure proper ventilation and maintenance access.

4. Energy Efficiency

Energy efficiency is another crucial factor to consider when selecting an industrial powder coating oven. A larger oven will consume more energy to heat and maintain the desired temperature. Consider the insulation, heating elements, and airflow design of the oven to ensure optimal energy efficiency. Investing in an energy-efficient oven can help reduce operating costs in the long run.

5. Future Expansion

When choosing the size of the industrial powder coating oven, it is important to consider your future expansion plans. If you anticipate business growth and increased production demands in the future, it may be beneficial to invest in a larger oven that can accommodate your future needs. This will help avoid the need for frequent upgrades or replacements as your business expands.

6. Budget Constraints

Lastly, consider your budget constraints when choosing the size of the industrial powder coating oven. Larger ovens with advanced features may come at a higher cost. Evaluate your budget and weigh it against the size and specifications of the oven to find a balance between cost and functionality. You may also consider financing options or leasing agreements to acquire the right size oven for your business.

Conclusion

Choosing the right size industrial powder coating oven is a critical decision that can impact the efficiency and productivity of your business. Consider factors such as the size of the parts being coated, production capacity, space constraints, energy efficiency, future expansion plans, and budget constraints when selecting the size of the oven. By carefully evaluating these factors and choosing a size that aligns with your business needs, you can enhance the quality of your powder coating process and optimize your operations.